This page explains the common heads we supply in Nylon, PP, PVC, PEEK and other polymers, and when to use them. For exact sizes, see the product pages.

Quick Highlights

-

Flush vs proud: Countersunk sits flush, while pan/cheese/socket/hexagon heads sit proud and spread load better on plastics. Add a washer if you need more bearing area.

-

Drive choice: Crosshead (Phillips/Pozidriv) gives better tool control than slotted; hex socket head (Allen) takes higher torque with less chance of cam-out. Slotted is basic and easy to damage under load.

-

Torque in plastics: Polymer screws need lower torque than metal. Stop at snug; use a torque driver where needed. Published nylon torque tables are much lower than steel.

-

Washers help: On plastics, a flat washer spreads load and reduces surface marking and creep. Most of our bolt sets include washers for this very reason.

- Our Bolts by Head Style — Browse here: https://caterpillar-red.com/nuts-bolts/

Head Types (What they are & Where they fit)

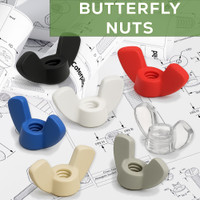

Butterfly Nut (Wing Nut)

Flat, wide wings for tool-free tightening. Good for panels, covers and fixtures that need frequent removal. Light-duty clamping only. Use a washer for plastics.

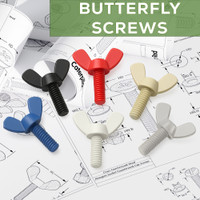

Butterfly Wing Bolts (Butterfly Screws)

Bolt with wing-style head for finger grip and quick adjustments. Best where tools are inconvenient. Keep loads modest; add a washer if you need more bearing area.

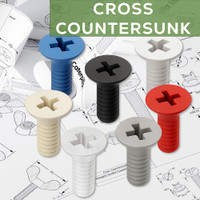

Crosshead Countersunk Screw

Tapered head that sits flush. Tidy finish and no snag points. Use where flush is required; avoid over-tightening in plastics — countersinks can concentrate stress. Use a washer for more load spread.

Crosshead Pan Head Screw

Rounded, low-profile head with broad underside. Versatile and kind to softer materials; common in electronics and general assembly. Better load spread than countersunk at the same size.

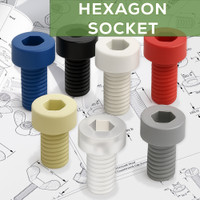

Socket Hex-Head (also known as Hex Socket & Cap Screw)

Cylindrical head with internal hex drive. Works well in tight spaces and takes higher torque with less slippage. Ideal where you need firm clamping but still want a compact head. In plastics, use a sensible torque limit.

Slotted Knurled Thumbscrew

Knurled sides for finger grip plus a slot for a screwdriver. Designed for frequent, fine adjustments and field access. Use for covers, guards and fixtures; not for high torque.

Slotted Pan Head Screw

Rounded, low-profile head with a single slot. Simple, universal drive, but easiest to cam-out and damage under higher torque. Choose only for light duty or where a slotted driver is the only option.

Hexagon Head Bolts (External Hexagon Head)

External hex for spanner/socket. Best for high clamping and easy removal. On polymer screws and nuts, set a conservative torque to avoid thread damage. Washers recommended on most substrates.

Slotted Cheese-Head Screw

Tall, cylindrical head with deep slot. Good tool engagement and a neat look; sits proud. Use where vertical headroom is available and you want more driver engagement than a pan head

Slotted Countersunk-Head Screw & Slotted Set Screw (Headless, Slotted)

Slotted Countersunk-Head Screw

Flush finish with a slotted drive. For visible faces and covers where a slot is acceptable. As with all countersunk in plastics, be cautious on torque.

Slotted Set Screw (Headless, Slotted)

Headless screw with a slot at the end. Used where space is tight or you need the fastener below the surface. Best for light to medium duty in plastics. Note: set screws are often headless and fully threaded

Hexagon Socket Countersunk Screw

Countersunk head with an internal hex. Sits flush and still takes an Allen key for better torque control than slotted/crosshead countersunk. Use on flat faces where a flush finish is critical; keep torque sensible in polymer.

Polymer-Specific Tips

Torque: Nylon and other polymer screws have lower torque limits than steel. Use a torque driver if repeatable results matter.

Washers: Use supplied flat washers to spread load and protect the surface, especially with pan/cheese/hex heads on softer plastics.

Countersinking plastics: Only where a flush face is essential. Keep the countersink clean and shallow; avoid over-tightening. If unsure, pick a pan or flanged head.

Repeated removal: Slotted and crosshead styles wear faster; hex socket and knurled/thumb designs are better for repeated adjustments in polymer parts.

Quick Chooser

Need tool-free: Wing or Knurled ThumbScrews.

Need tool-free: Tight space, higher control: Hex Socket.

Need Flush Face: Countersunk (watch the torque)

Need Best Load spread: Pan Head or Hexagon Head. The latter is our preference.

Need Hide the fastener: Set Screw (headless) where design allows.

Micro-FAQ

Countersunk in plastic or not?

- Only if you need it flush. It can concentrate stress. A Pan, Hex or Socket Head with a washer spreads load better.

Phillips or Pozidriv?

- Pozidriv usually takes more torque and is less likely to slip; a Phillips driver in a Pozidriv screw can slip and damage the head.