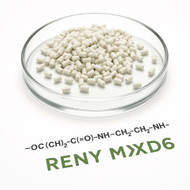

RENY Glass-Fiber Reinforced Polyamide MXD6: Mechanical Strength and Dimensional Stability

History

The advancements of the late 20th century in developing alternative materials to replace metals for manufacturing lightweight yet durable parts led to the discovery of RENY (also known as MXD6). To meet the growing demand for materials resistant to extreme conditions, Mitsubishi Engineering-Plastics Corporation developed RENY, a high-performance polyamide material primarily reinforced with glass fibers to enhance mechanical strength. RENY, therefore, belongs to the class of engineering plastics. It quickly gained popularity in the automotive, electrical, and industrial sectors due to its excellent mechanical properties and enhanced resistance to harsh conditions.

Quick Highlights

- The growing demand for resistant materials to replace metals drove the discovery of RENY by Mitsubishi Engineering-Plastics Corporation in the late 20th century.

- RENY is a high-performance polyamide primarily reinforced with glass fibers.

Synthesized

RENY is synthesized through the polymerization of polyamide 6T. During the manufacturing process, hexamethylenediamine (HMD, supplying the amine functionality) and terephthalic acid (TPA, supplying the carboxylic acid functionality) undergo condensation to form amide bonds, releasing water as a byproduct. This reaction is generally performed at high temperatures (up to 300 °C or 572 °F) in the presence of a catalyst to accelerate reaction times. The molten polyamide is then blended with reinforcing fibers, stabilizers, and additives to fine-tune the properties of end products. Finally, the blended material is processed via extrusion or molding.

Quick Highlights

- RENY is synthesized through the polymerization of hexamethylenediamine and terephthalic acid at high temperatures in the presence of a catalyst.

- The molten polyamide is blended with reinforcing agents (glass fibers or carbon fibers) and other additives and then processed via extrusion or molding.

Tensile Strength

As a semi-aromatic compound, TPA introduces rigidity to the polymer backbone, providing RENY with mechanical strength and thermal resistance. Reinforcing fibers are typically added during polymerization to enhance mechanical strength. Glass fibers, the most commonly used, increase rigidity, tensile strength, and resistance to moisture and heat. Alternatively, carbon fibers offer similar benefits while improving electrical conductivity and reducing weight. Strong adhesion between the polymer matrix and fibers is crucial for optimal performance and can be achieved through surface treatments or coupling agents. Achieving the desired molecular weight of the polyamides during manufacturing presents another challenge.

Quick Highlights

- Terephthalic acid gives the polyamide its semi-aromatic nature and introduces rigidity to the polymer backbone.

- Glass fiber reinforcement increases rigidity, tensile strength, and resistance to moisture and heat. Carbon fibers provide similar benefits with improved electrical conductivity and lighter weight.

Mechanical Properties

RENY exhibits exceptional mechanical properties. It has excellent tensile and flexural strength, further enhanced by the reinforcing fibers (either glass or carbon), allowing it to withstand heavy mechanical loads and maintain structural stability in harsh conditions. Due to its stiffness and high strength-to-weight ratio, RENY serves as an excellent substitute for metals in various applications. Additionally, it absorbs impacts without cracking under stress, balancing rigidity and flexibility. It also maintains its shape under varying loads and temperatures, a crucial feature for precision applications such as automotive or aerospace components.

Quick Highlights

- RENY exhibits exceptional tensile and flexural strength, further enhanced by reinforcing agents. It is stiff and has a high strength-to-weight ratio.

- It absorbs impacts without cracking, demonstrating a good balance between flexibility and rigidity, and maintains its shape under varying loads and temperatures.

Thermal Properties

Thermally, RENY resists temperatures up to 150 °C (302 °F) and even higher temperatures for short durations. While RENY is processed at 250 to 280 °C (482–536 °F), temperatures should not exceed 300 °C (572 °F) to avoid thermal decomposition. The glass fibers provide good dimensional stability, minimizing thermal expansion. RENY’s thermal expansion coefficient is comparable to that of metal alloys.

Quick Highlights

- RENY exhibits good thermal stability, withstanding temperatures of up to 150 °C (302 °F) and higher for brief exposure, but thermal decomposition occurs above 300 °C (572 °F).

- Its thermal expansion coefficient is comparable to metal alloys, and glass fiber reinforcement ensures dimensional stability across varying temperatures.

Chemical Resistance

Chemically, RENY exhibits good resistance to most weak acids and alkalis, oils, greases, fuels, and certain organic solvents. However, it is susceptible to degradation from prolonged exposure to strong acids and oxidizing agents. RENY absorbs less moisture than traditional polyamides, reducing swelling and degradation in humid conditions. Additionally, it resists hydrolysis, maintaining its properties even when exposed to steam or hot water.

Quick Highlights

- RENY exhibits good chemical resistance to weak acids, alkalis, oils, greases, fuels, and some organic solvents but is vulnerable to strong acids and oxidizing agents.

- It has a lower moisture absorption coefficient than traditional polyamides and resists hydrolysis, retaining its properties in steam, hot water, or humid conditions.

Wear Properties

RENY’s excellent wear resistance makes it suitable for moving parts such as gears, bearings, and bushings. It resists abrasion, maintaining performance over prolonged use. It also withstands cyclic loading, exhibits high fatigue resistance, and resists creep under sustained loads.

Quick Highlights

- RENY exhibits excellent abrasion resistance and maintains performance over extended periods.

- It performs well under cyclic loads and exhibits high fatigue and creep resistance.

UV & Other Properties

RENY has moderate UV resistance, though prolonged sunlight exposure may cause surface degradation or discoloration. Adding UV stabilizers during processing can mitigate this limitation. Additionally, it exhibits good resistance to gamma and X-ray radiation, making it suitable for medical and nuclear applications.

RENY exhibits good electrical insulation properties, suitable for electrical and electronic components. Adding carbon fibers can further improve its conductivity. While not inherently flame-retardant, additives can make it flame-retardant to meet safety standards.

Quick Highlights

- RENY has moderate UV resistance, which can be enhanced through UV stabilizers added during processing.

- It also has good resistance to gamma and X-ray radiation, enabling applications in medical and nuclear fields.

- RENY has excellent electrical insulation properties, which are used to advantage for electrical and electronic components.

- Flame-retardant properties can be achieved with specific additives to meet fire safety standards.

Sustainability

While RENY is an important high-performance engineering plastic, its environmental impact is significant. Manufacturing glass-reinforced polyamides is energy-intensive, resulting in carbon emissions. Though its durability reduces waste over time, its non-biodegradability contributes to environmental persistence when not disposed of properly. Recycling efforts are limited due to the material's complex composition, containing varying degrees of glass fibers and additives. Addressing these challenges requires innovative recycling technologies, greener manufacturing practices, and improved waste management.

Quick Highlights

- RENY has a considerable environmental impact due to energy-intensive manufacturing and limited recycling.

- Advancements in recycling technologies, greener manufacturing, and improved waste management are necessary to mitigate its environmental impact.